There is much discussion these days about the benefits of strategic financial planning as it relates to revenue-cycle issues. Coding, billing, and reimbursement occupy a significant mindshare of financial and business managers -- understandably, as these areas of healthcare continue to become more complex and their mastery a fundamental requirement. Strategic financial planning should include an examination of all available options to manage costs, as well as revenue.

While some costs associated with equipment utilization change, others do not. One significant fixed operational expense is business and medical equipment service costs. Service plans have to take into consideration equipment age, daily usage, risk tolerance, and cash flow. As expensive multiyear original equipment manufacturer (OEM) service contracts expire, lower-cost alternative service solutions should be considered. Options include not only use of third-party independent service contracts and time-and-materials service, but also equipment maintenance insurance (EMI).

Equipment maintenance insurance, long used by hospitals to reduce service expenses while enabling the transition to self-insurance, is gaining notice by outpatient imaging business managers as a viable means to manage the risk associated with long-term service expenses. EMI can be likened to a buying group of service agreements.

One of the most attractive features of an EMI program is the excellent reporting tools that give customers insight into their actual service costs. This feature, combined with the immediate 15% to 20% savings over typical service contracts, is very attractive to the outpatient healthcare market. Customers are able to use their vendors of choice, as EMI is a financial tool and not a repair company.

Current business environment

Imaging center operators are beginning to feel new financial pressures, due to the expansion and maturation of the outpatient imaging business, particularly in the larger urban centers with a disproportionate Medicare/Medicaid population, and because of the recently implemented reimbursement cuts from the Deficit Reduction Act (DRA) of 2005. As a result, imaging center owners and their managers must seek additional programs for cost management to complement revenue-cycle-management efforts. Additionally, increasingly stringent equipment standards being implemented by many payor organizations, such as utilization management firm CareCore National of Wappingers Falls, NY, are putting additional cost pressures on already strained organizations.

New equipment purchases offer imaging providers an opportunity to consider alternative service programs before entering into costly multiyear OEM service agreements. There are few alternatives for managing and reducing service costs in the outpatient imaging business. Full-service maintenance agreements are purchased at the time of equipment acquisition, often with the assumption there are no alternatives. While these full-service agreements have their place, they are not necessarily the best solution to all situations.

Service contracts were initially developed by OEMs to simplify the management of their very complex and sensitive imaging systems. Service contracts have since expanded into convoluted and highly profitable programs, typically incorporating many features with unmeasurable financial value bundled with the actual repair and maintenance terms.

A delicate balance

A majority of the over 5,000 outpatient imaging centers in the U.S. are individually owned and operated by small physician groups. These centers have succeeded by keeping operating costs low and serving the immediate needs of local referring physicians. The inherently low cost structure of outpatient imaging would be upset if centers employed personnel dedicated to the continuous management of service-contract purchases, as is the standard practice in the hospital environment. Nor can most imaging centers afford to employ engineering personnel to lower the cost of servicing equipment.

Therefore, the perception persists that long-term contracts are the only available and most cost-effective option for fixing long-term service costs and ensuring equipment is repaired in a timely fashion. Over time, the only means to judge the value of service contracts is the responsiveness of the service provider in keeping the systems operating. Actual financial value is masked in these contracts because of the lack of reporting capability and access to actual costs.

Knowledge of current service costs, and the ability to use service information to continually reduce service expenses, is a prerequisite to ongoing management of operational service costs. This is especially true for entities with equipment in many locations or with more than one piece of the same equipment.

While typical service reporting is limited to information made available by the service provider and encompasses tracking of invoice status, service performed, and covered service costs, this is inadequate detail to enable service-cost management and assessment of service value. Detailed information should be available 24/7 via the Web and should encompass equipment performance data, actual repair costs, and comparison of data across service vendors, as well as the ability to generate customized reports of any kind. Programs such as equipment maintenance insurance are designed to address this need and clarify, rather than mask, actual service costs.

Fear of the unknown

Healthcare markets, which are notoriously conservative in accepting change, are being impacted by rapid changes on many fronts. These changes naturally create an environment of fear among those responsible for navigating these uncertain waters. Fear of making a change, to adapt. Fear of staying the course while the world changes around you. Fear of change and trying something new is a real barrier to all of us, and limits our ability to see new opportunities. Fear can also prevent us from doing what is needed because of fear of repercussions. Those involved in the outpatient imaging business are being forced to consider new strategies and adopt new tactics to address today's challenges.

For those who have historically viewed full-service agreements as something purchased along with the equipment and nothing more, strategic reassessment of service costs and the options for reducing them might be a quick exercise; no choice but to continue the status quo. For those who see service contracts as a risk-management tool for keeping equipment running, options abound. Many are choosing to renegotiate service contracts with their existing vendors, while others are taking another look at third-party independent service organizations and equipment maintenance insurance.

Over the last 20 years the imaging equipment market has segmented into two classes: equipment that is under a full-service agreement and equipment that is not. While the value of a full-service agreement is undeniable for a new state-of-the-art MRI, CT, or PET/CT scanner, many other classes of imaging and support equipment are excellent candidates for alternate service risk methods such as equipment maintenance insurance.

Equipment that is five years old or older, coming off service contract, or currently under time and materials service, as well as refurbished equipment, make excellent candidates for EMI, as its value has depreciated significantly while its ability to generate profits remains high. The need to reduce operational service expenses must be balanced against risk tolerance, as one weights the benefits of moving from full-service contracts, the least risky, to time and materials, the most risky. EMI provides a balanced vehicle, with risk falling between the two while fixing costs at a low level.

The fear of increased system downtime and the potential to alienate existing service vendors may prevent a center from exploring alternative service-contract vehicles. While downtime is obviously critical to avoid, the relationships all providers have developed with their service vendors are there to be leveraged both ways. Providers should be confident that their business' financial health comes first, and if a service provider is unwilling or unable to provide a high level of service, regardless of the context, many others are willing to address their needs.

Real-world example

Service-expense management is typically performed retrospectively because of a lack of available data required for planning. Subsequently, decisions about how service risk should be managed are made through a combination of perception, age, and usage-related factors.

Typically the following tangible categories are used to define which long-term service risk management tool is used:

|

In addition, capital equipment often falls into various emotional categories that affect decisions about how equipment service should be managed:

- Deemed reliable (doesn't break down)

- Only one of its kind at the facility

- Technologically disposable

- Doesn't cost a lot to repair

- If it breaks, it won't affect revenue (much)

While human nature will always influence how we justify our decisions, the business world has less tolerance for unsound business practices. Strategic business decisions must account for the unknown and protect business interests from inevitable change. Historical cost information, as well as service vendor and equipment reliability data, should all be used to assess how best to manage service expenses.

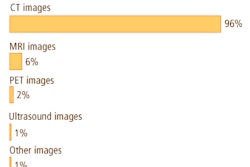

Below is a chart of a single imaging center's medical and business equipment inventory and associated service costs, providing an actual example of how equipment maintenance insurance can be used to manage long-term service expenses. While each facility's actual cost will vary and be impacted by many factors, the goal is to focus attention on long-term cost savings, not immediate one-year savings.

Actual service contract costs include "off-contract" expenses because of service needing to be performed outside the hours of the contracts.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Medical equipment three-year savings: $168,060 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

While measurable immediate savings is always the goal, the attitude that no savings is too small should always be brought to bear. This is especially true for multicenter companies where savings can quickly accumulate over time and across facilities. In addition, an ongoing effort must be made to gather service-performance data so that quarterly assessments of actual results can be compared to expectations. Only under these circumstances can a strategic financial approach to service expenses be realized.

Actionable items

Organizations committed to a strategic approach for managing service and ultimately considering equipment maintenance insurance must be committed to organizing their financial service information to clearly understand their annual service costs. As with most choices, the simplest option is not always the most cost-effective. The organization must commit to pursuing alternatives because the first critical step is gathering information about the current business environment.

Gathered information must include the following 12-month costs:

- Annual service contract expenses

- Annual time-and-materials expenses

- Annual "off-contract" service expense

All three components must be included to create a clear picture of actual current service expenses. Once a clear picture of actual service costs is created, is it possible to determine what cost-savings measures can be taken. While this might seem obvious, years of automatically purchasing service contracts, each with its own expiration date, cost, and invoice date, has been known to create a rat's nest of information, making it difficult for even the most organized business managers to know their center's exact service costs.

Financial information can be organized per the following example:

From this detailed information a clear picture of costs will emerge that can be compared to expectations and other operational expenses.

This information should be updated annually, particularly for time-and-materials equipment or for equipment whose service-contract status has changed. In addition, data should be updated if any of the following events occur:

- Purchasing a new center

- Selling a center

- Upgrading or expanding the capabilities of existing equipment

- Dissatisfaction with existing service providers

Conclusion

Strategic financial expense planning is just as important as revenue-cycle management, with particular attention paid to fixed expenses such as service. Equipment maintenance insurance should be part of any imaging center's strategic plan to reduce long-term operating expenses, in conjunction with appropriate use of OEM service contracts and in-house service.

For larger multicenter practices considering hiring an in-house engineer, the use of equipment maintenance insurance will help determine whether this is a cost-effective alternative. As with any service contract, operational requirements, risk tolerance, and cost-effectiveness should be considered when determining whether a multiyear OEM service contract, EMI policy, or time-and-materials program is best for a particular piece of equipment. Ultimately, a mix of all three programs may be best.

By Dean Kaufman

AuntMinnie.com contributing writer

June 8, 2007

Mr. Kaufman is director of business development for Herman Risk Management, a Rockville, MD, company that offers insurance-backed equipment maintenance agreements. He can be reached at 877-466-4476 or [email protected].

Related Reading

Details drive service contract negotiations, August 10, 2005

Copyright © 2007 AuntMinnie.com

|