For planning neurosurgery with CT images, radiologists in Hawaii have begun using automated 3D models -- produced far more cheaply than with earlier methods -- to provide surgeons and patients with information that can't be replicated on a flat computer monitor. A demonstration project this week at the American Roentgen Ray Society (ARRS) annual meeting in Chicago is showing how it's done.

MDCT scanners produce excellent high-resolution images for surgical planning. But neurosurgeons have found that images on a screen -- even high-resolution 3D images -- are of limited use compared to solid 3D models that can be held in the hands, according to Michelle Yoshida and colleagues from Tripler Army Medical Center in Honolulu.

"Radiologists can understand 3D without a model, but patients have trouble," co-investigator Dr. Lynne Ruess said in an interview with AuntMinnie.com. "Surgeons use it for complex anatomy, and they also use it to model prostheses like a skull cranioplasty flap."

The 3D models can show pathology with greater clarity and depict morphologic changes after treatment, Yoshida said in a statement.

|

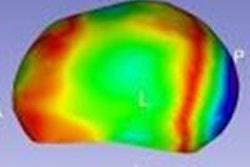

| 3D model of infant with complex skull deformity (craniosynostosis) used for parent education and neurosurgical planning. All images courtesy of Dr. Lynn Ruess. |

|

The printer (Z Corporation) costs approximately $40,000, and each 3D model costs about $250 in materials, Ruess said.

The researchers learned that the local forensics lab at Tripler was using the printer to create models of soldiers' remains to aid in identification, and they made a deal to incorporate it into the radiology department. The project is a joint collaboration between Tripler Army Medical Center and the Joint POW/MIA Accounting Command (JPAC) Central Identification Laboratory in Hawaii.

"It's a powder and a glue that's basically laid down in layers," Ruess said of the process. "It's an inkjet printer technology that lays down a thin layer of powder and then some glue, then another layer of powder. When the model is done ... you have to brush off the excess powder and only the glue remains."

The printer can model almost anything smaller than a shoe box. Architects use it to build models of homes, and engineers can use it to make fittings and screws, for example.

The ARRS demonstration project illustrates the utility of the printer in applications such as craniosynostosis, cranioplasty, and spine surgery.

Previously, Tripler doctors were sending data from Hawaii to the mainland U.S. to have models made at great expense and considerable time. "We are applying the technique ... on complicated anatomy and pathology" to help surgeons communicate with patients and their families, Yoshida said.

![Images show the pectoralis muscles of a healthy male individual who never smoked (age, 66 years; height, 178 cm; body mass index [BMI, calculated as weight in kilograms divided by height in meters squared], 28.4; number of cigarette pack-years, 0; forced expiratory volume in 1 second [FEV1], 97.6% predicted; FEV1: forced vital capacity [FVC] ratio, 0.71; pectoralis muscle area [PMA], 59.4 cm2; pectoralis muscle volume [PMV], 764 cm3) and a male individual with a smoking history and chronic obstructive pulmonary disorder (COPD) (age, 66 years; height, 178 cm; BMI, 27.5; number of cigarette pack-years, 43.2, FEV1, 48% predicted; FEV1:FVC, 0.56; PMA, 35 cm2; PMV, 480.8 cm3) from the Canadian Cohort Obstructive Lung Disease (i.e., CanCOLD) study. The CT image is shown in the axial plane. The PMV is automatically extracted using the developed deep learning model and overlayed onto the lungs for visual clarity.](https://img.auntminnie.com/mindful/smg/workspaces/default/uploads/2026/03/genkin.25LqljVF0y.jpg?auto=format%2Ccompress&crop=focalpoint&fit=crop&h=100&q=70&w=100)

![Images show the pectoralis muscles of a healthy male individual who never smoked (age, 66 years; height, 178 cm; body mass index [BMI, calculated as weight in kilograms divided by height in meters squared], 28.4; number of cigarette pack-years, 0; forced expiratory volume in 1 second [FEV1], 97.6% predicted; FEV1: forced vital capacity [FVC] ratio, 0.71; pectoralis muscle area [PMA], 59.4 cm2; pectoralis muscle volume [PMV], 764 cm3) and a male individual with a smoking history and chronic obstructive pulmonary disorder (COPD) (age, 66 years; height, 178 cm; BMI, 27.5; number of cigarette pack-years, 43.2, FEV1, 48% predicted; FEV1:FVC, 0.56; PMA, 35 cm2; PMV, 480.8 cm3) from the Canadian Cohort Obstructive Lung Disease (i.e., CanCOLD) study. The CT image is shown in the axial plane. The PMV is automatically extracted using the developed deep learning model and overlayed onto the lungs for visual clarity.](https://img.auntminnie.com/mindful/smg/workspaces/default/uploads/2026/03/genkin.25LqljVF0y.jpg?auto=format%2Ccompress&crop=focalpoint&fit=crop&h=112&q=70&w=112)