Organic food is said to be healthier -- and going organic in x-ray imaging could be too, according to research on a newly developed flexible x-ray panel sensor. The study was published online on August 4 in Nano Letters.

In a proof-of-concept study, a team of U.S. and Chinese researchers created a flexible x-ray imaging device that uses nontoxic materials (metal-organic frameworks, or MOFs) in its sensor panel rather than heavy metals, which have been shown to cause adverse health effects over long periods.

"This study provides a pathway toward the potential utilization of metal-organic frameworks for emerging radiation monitoring and imaging applications," wrote Shuquan Chang, PhD, of Nanjing University of Aeronautics and Astronautics.

Current flat panel x-ray detectors used in mammography exams, for instance, are rigid and uncomfortable for patients. In the past few years, advances have been made in developing flexible sensing devices that can be readily shaped to fit in "nonplanar" scenarios. However, even in this advanced field, active sensing materials for x-ray panels are made with heavy metals, such as lead and cadmium.

In this study, the researchers sought to create a new type of x-ray detection panel that combines mechanical flexibility with lead-free materials, or metal-organic frameworks (MOFs), which, in addition, are highly conductive and may be more sensitive for detecting x-ray emissions than standard materials.

"To the best of our knowledge, the utilization of low-Z (atomic number) semiconductive MOFs for x-ray detection is first investigated, which provides the possibility for a nontoxic and cost-effective flexible x-ray detector," the team wrote.

First, the researchers dissolved a material known as DABDT (2,5-diamino-1,4-benzenedithiol dihydrochloride) together with nickel (Ni) in a three-neck glass flask. The MOFs essentially "self-assembled" via chemical reactions in the flask after six hours at room temperature. The study authors used a centrifuge to separate the MFOs and produced the product -- a final black solid mass -- after drying it in a vacuum oven for 12 hours at 70° C.

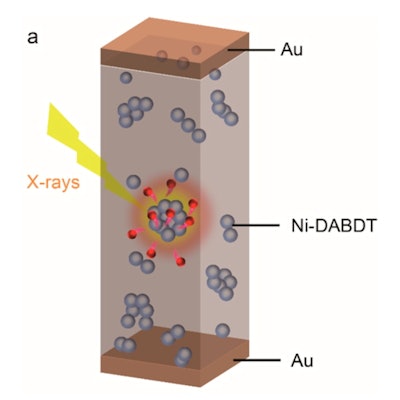

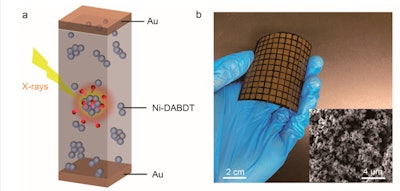

To make the flexible x-ray radiation detector, the team "sandwiched" the nickel-containing MOF between gold film electrodes, one of which was on a flexible plastic surface. They used copper wires to transmit current from each pixel of a 12 x 12 array and covered the whole device with a silicone-based flexible polymer.

(a) A schematic diagram of a flexible x‑ray detector architecture composed of Ni-DABDT as an absorbing layer and (b) a photograph of the flexible x‑ray detector device based on Ni-DABDT. Image courtesy of Nano Letters.

(a) A schematic diagram of a flexible x‑ray detector architecture composed of Ni-DABDT as an absorbing layer and (b) a photograph of the flexible x‑ray detector device based on Ni-DABDT. Image courtesy of Nano Letters.In initial tests, the nickel-containing MOF was more sensitive than other recently reported flexible detectors when irradiated with 20 keV x-rays -- the equivalent to the energy released during medical diagnostic imaging, according to the researchers.

In addition, after 10 hours of x-ray irradiation, there was only a 2% drop in photocurrent, which indicates superior radiation robustness under the operating conditions, and after 500 repetitions of bending, the flexible Ni-DABDT detector showed an excellent mechanical stability, the team reported.

Ultimately, the researchers stated that their proof-of-concept device is a step forward in developing the next generation of flexible radiology imaging equipment.

"A new type of x-ray detection material that could combine the advantages of [lead]-free, high-detection sensitivity, and mechanical flexibility is of great interest for x-ray detector applications," Chang et al concluded.