U.S. researchers have developed a new type of computed radiography (CR) technology that they believe could yield much higher resolution than existing CR systems. One prominent scientific magazine thought enough of their research to name it one of the top 100 scientific innovations for 2007.

Computed radiography has made impressive gains in achieving commercial acceptance in the last 25 years, but the fundamental technology behind CR remains the same -- photons produced by an x-ray generator are sent through a patient and captured on a storage phosphor plate that's coated with a powder that typically consists of barium fluorobromide doped with europium. The imaging plate is then taken to a laser scanner, where electrons stored in the plates are converted into light, then read out and converted into digital images.

But some industry observers believe that CR has reached a plateau in terms of improving on this basic design, and as a result its image quality has been surpassed by digital radiography (DR) units based on flat-panel technology, according to a research group that includes scientists from Argonne National Laboratory in Argonne, IL, and the State University of New York (SUNY) at Stony Brook. To improve on CR, the group developed a new type of storage phosphor material based on a translucent glass-ceramic imaging plate.

The SUNY/Argonne technology could offer much higher resolution than current CR systems, and could be used to retrofit existing x-ray rooms in the same way as CR, without requiring a new x-ray generator and other equipment, according to Anthony Lubinsky, who represented SUNY on the research team. Lubinsky is a former employee at Eastman Kodak Health Group (now Carestream Health of Rochester, NY), and has been working on CR technology for the past 20 years.

"It would be as easy to make the switch (to digital) for your x-ray room as it is with CR in the ordinary practice," Lubinsky said. "What's inside the cassette is different and what's inside the scanner box is also different, but to the user it works the same way."

See-through CR?

The heart of the new technology is a CR design developed at SUNY and Argonne National Laboratory that the group calls transparent storage phosphor (TSP). TSP is based on a photostimulable material that employs fluorozirconate rather than barium fluorobromide. Rather than coat an imaging plate with the fluorozirconate, the material is used in combination with europium-doped barium nanocrystals to create a composite glass imaging plate.

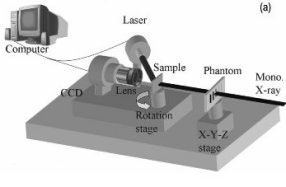

|

| Experimental setup of x-ray imaging system for testing fluorochlorozirconate glass-ceramic imaging plates. |

The SUNY/Argonne design results in a detector material that's translucent, rather than the opaque powder screen used today with CR. As a result, a point of light entering the imaging plate doesn't scatter as much as it does with conventional imaging plates, resulting in a higher modulation transfer function (MTF). That means that a manufacturer developing a CR system based on the SUNY/Argonne technology could make the imaging plate much thicker than one based on barium fluorobromide or some other type of powder, with correspondingly higher spatial resolution.

How much higher? The group has fashioned imaging plates with a resolution of 17 microns, compared with 70 microns for amorphous selenium-based DR and 100-200 microns for conventional CR, according to Jacqueline A. Johnson of Argonne National Laboratory. The group points out that the 17-micron specification was achieved in a test environment and with a radiation dose that's much higher than would be used clinically.

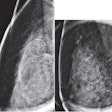

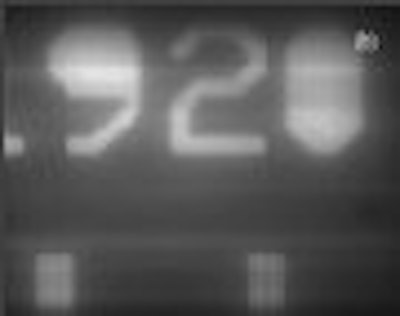

|

| Phantom image collected with tabletop CR system. Parallel vertical lines represent gold bars at spatial frequencies of 19 line pairs (left) and 20 line pairs (right) per mm. All images courtesy of Argonne National Laboratory. |

One of the most obvious applications for the SUNY/Argonne technology in the clinical realm would be mammography, in which CR units based on conventional technology are entering clinical use in the U.S. after the Food and Drug Administration's 2006 approval of the first CR mammography unit, from Fujifilm Medical Systems USA of Stamford, CT. Argonne's technology could give mammographers an even finer level of detail than conventional CR.

But the Argonne team believes that its technology could have a wide range of applications in medical imaging. "If it works for mammography, I would hope the resolution would be helpful in the extremities as well," Lubinsky said.

However, you won't see the SUNY/Argonne technology in a commercially available CR system anytime soon. At present, the group has built a tabletop system and collected phantom images, and their next step is to develop a working prototype. The research team estimates that it could be more than five years before the technology hits clinical users, due to the vagaries of technology development and the need to move such a system through the FDA approval process.

If the technology does make it into the commercial marketplace, it wouldn't be totally plug-and-play with existing CR systems. Although the technology could be used with existing x-ray generators and gantries, the TSP plates would require specially adapted scanners for reading the plates, according to Lubinsky.

But the SUNY/Argonne's team work was promising enough to catch the attention of R&D Magazine, which named the research one of the top 100 scientific innovations of 2007, based on the group's March 2007 paper in the Journal of the American Chemical Society (Vol. 90:3, pp. 693-698). The award will be announced in the magazine's September issue.

The development of a translucent CR imaging plate is not a new idea: "It's something that people have thought of as a great idea if you could do it," Lubinsky said. But the SUNY/Argonne group's major achievement has been in developing both a translucent imaging plate and the concept of a laser scanner to read out the images.

"The trick is to get the (TSP and readout technologies) working together so well," he said.

By Brian Casey

AuntMinnie.com staff writer

September 3, 2007

Related Reading

PACS data-mining technique tackles CR dose creep, July 30, 2007

DICOM-compliant displays aid CR/DR exposure control, July 17, 2007

CR/DR image quality: Issues and concerns, April 12, 2007

Strategies for reducing 'dose creep' in digital x-ray, April 11, 2007

Study suggests ways to cut CR radiation, March 5, 2007

Copyright © 2007 AuntMinnie.com