No matter the size of a hospital, healthcare facility, or imaging center, caring for radiology equipment is a critical component in maintaining uptime, patient care, and revenue. If a CT scanner, MRI system, or ultrasound device goes down, then patients are inconvenienced, healthcare is delayed, and the facility suffers from a loss of revenue and poor public image.

In the first of a two-part Trends in Radiology series on equipment service, we look at how three healthcare systems have crafted their service strategies. These institutions represent the evolution of service in medical imaging, in which straight service deals between equipment owners and vendors are being replaced by more collaborative arrangements in which a facility's in-house staff works with OEM engineers. Many facilities believe these kinds of deals offer the right mix of high response time at an affordable cost.

How much should service cost?

-- Al Gresch, Aurora Health Care, Milwaukee

Aurora reorganized its in-house service team in January 2006, making four regional managers responsible for one of four specific groups of modalities. The healthcare system also trained its service staff of 69 full-time-equivalent engineers to become specialists in one primary modality, with secondary knowledge and responsibility for another modality.

With Aurora handling 85% to 90% of its service calls internally, the new in-house structure has helped maximize both response time and, subsequently, uptime. If outside vendors want a piece of Aurora's service business, they need to offer comparable benefits. "If we are in a situation where I want a service contract, response time will be huge," he added. "Given the size of our organization, many vendors are reluctant to get that response time to where we would like to have it."

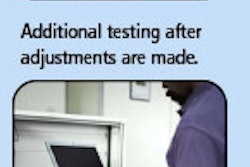

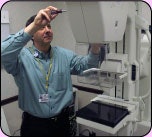

Steve Sellitto, a biomedical imaging lead at Aurora Health Care, services a mammography unit. Image courtesy of Aurora Health Care.

As Gresch explains, it is one thing for a vendor to promise guaranteed response time in Milwaukee; it is another issue to commit to a response time with an Aurora facility in the far reaches of Wisconsin.

Contract negotiations

OSF Health Care, based in Peoria, IL, is in a similar situation as Aurora. With five hospitals spread across northern Illinois, one hospital in Michigan, and several outpatient facilities with imaging and outpatient surgery capabilities, responding to service calls promptly is a priority, whether it be with internal staff or an outside vendor.

Currently, OSF has six clinical engineers who handle first-call response for 19 MRI systems, 14 CT scanners, two PET/CT units, and more than 100 other pieces of radiology equipment among the hospitals. OSF also has two engineers stationed full-time at each hospital. His service team handles approximately 87% of service calls before relying on outside help.

-- Dale Surratt, OSF Health Care, Peoria, IL

Surratt oversees OSF's mobile imaging and equipment technology service businesses, and sees the gamut of service deals, from full-service, all-the-time agreements to time-and-materials contracts, based on years of equipment repair and service history. He believes there are a number of components that absolutely must be included in any service contract (see sidebar at left).

Collaborative efforts

Since joining Johns Hopkins Hospital in Baltimore 21 years ago, Michael Harris, head of radiology, physics, and engineering in the hospital's radiology department, has seen an evolution in the working relationship between in-house service staff and outside service vendors.

Biomed engineer Chris Warren of OSF Health Care works on an endoscope. Image courtesy of OSF Health Care.

Harris met with outside vendors to craft a collaborative approach to equipment service, sharing the mutual benefits and the risks. In the contractual arrangement, Johns Hopkins, like many healthcare facilities, handles the first response on service calls for the majority -- if not all -- of its imaging equipment. In turn, the outside vendor rushes needed parts to the facility right away and offers assistance on critical problems.

"We have value by being inside the institution with the ability to respond to calls much quicker," Harris said, "while they have wider resources and they manufacture the parts."

Today, Johns Hopkins' internal staff handles approximately 80% of its service calls, while outside vendors take care of the rest. The remainder includes the most severe equipment issues and covers for in-house engineers when they are consumed with other calls.

"We have such a strong collaboration with all our equipment suppliers that they cooperate very highly with us," Harris said. "With the large number of devices we have -- and since they are largely high-end devices -- it is impractical for a small group (of service technicians) to be trained on every system, other than to have a knowledge well enough to determine that the problem is so severe that it needs intervention by outside engineers."

Have no fear

Tom Horner, Aurora biomedical imaging tech, works on a CT scanner. Image courtesy of Aurora Health Care.

"We push the vendors hard to provide us with greater service offerings than they did in the past," Gresch said. "Usually you either had full service that offered 24/7 coverage with all parts provided, or there was a step down to full parts and coverage Monday through Friday from 8 to 5. Maybe there was some level of in-house ability where you did the (preventive maintenance)."

Gresch said a key piece of advice is to "never allow fear to make decisions for you." "Collect the data and make decisions based on that data," he advised. The vendor may offer a service contract for, say, $15,000 per year, asserting that if a component goes bad, the facility has justified the expense.

"That is a reasonable argument, but if I have 20 of those devices, is that part going to fail on all 20 devices?" Gresch said. "What has been the failure rate on those boards? Look at the rate of parts failure and how much it costs to replace it. Then make the decisions based on that data, not on fear."

Strategic planning

Loyola University Health System, based in Maywood, IL, also relies heavily on its in-house staff for service to handle more than 90% of its calls.

Within Loyola, more than 300 imaging devices, ranging from new to mature technologies, are spread among the main campus -- Loyola University Medical Center -- and 15 primary care centers and one major imaging center throughout the greater Chicago area. Loyola's outpatient clinics offer mammography and general radiography, while the offsite imaging center features MRI, CT, and general radiography.

The service staff of 23 clinical engineers is divided into four units: imaging, OR/biomedical, general biomed, and laboratory. Three divisions have seven technicians, while the laboratory group has two technicians.

"We are the primary service provider internally," said Al Moretti, Loyola's director of clinical engineering. "We, in turn, work through the OEM for their respective devices. We do very little third-party service at all, because our role is to do 95% of the work internally."

-- Al Moretti, Loyola University Medical Center, Maywood, IL

"We have a large installed base, but we are able to employ staff onsite that are of OEM caliber," Moretti said. "It may not be the model for every institution. If you are a smaller institution with a smaller installed base, you may have to look at other objectives on how to save time and costs."

Moretti's advice to other healthcare institutions is to understand the facility's business plans for the imaging modalities, understand the capabilities and resources on hand, and understand what you can achieve for a service with the available resources. "Without looking at those three, that's when the failures come about," he added. "An organization will come up with a plan and ideas that it wants to achieve, but without having a skill set of individuals, resources, training, and tools, there can be a large margin of error."

By Wayne Forrest

AuntMinnie.com staff writer

March 1, 2007

Copyright © 2007 AuntMinnie.com