Radiologists train and prepare for interventional radiological procedures often using costly anatomical phantoms that are not patient-specific, Dr. Philipp Brantner, co-head of University Hospital Basel's 3D Print Lab, told AuntMinnie.com.

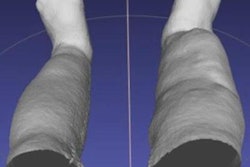

Seeking to establish a more practical approach to simulating complex interventions, Brantner and colleagues joined silicone molding with fused deposition modeling 3D printing to create affordable patient-specific replicas of vessels.

They ultimately developed a stenosis model by printing the negative form of the stenosis with a fused deposition modeling 3D printer and casting it with clear, flexible silicone at an estimated price of $10.

"Not only will this allow residents to train on a model to become familiar with vascular procedures in a cost-effective manner, but it will also enable experienced interventional radiologists to practice and plan complicated interventions prior to the actual angiography," Brantner said. "In the future, we hope to create our own low-cost angiography simulator based on open-source hardware and to expand on creating not only generic stenoses but also patient-specific and more complex vessel variants."